In light of the terrible train derailment tragedy in La Megantic this week, one question is “why are risk assessments so underestimated?”

Engineers, scientists, and managers do risk assessments all the time as a normal course of business. Yet system failures occur much more frequently than the risk assessments report.

Typical Nuclear power industry/regulator estimates of core damage frequency are between 1 in 20,000 or 1 in 50,000 reactor years, which mean a core damage incidence every 40-100 years; or in our history, there should have been less than 1 incidence so far. Yet so far we have had more than 10 such incidents. The risk assessment and management methodology in this case is underestimating the risk by over an order of magnitude.

While it is too early still to understand the root cause and systemic failures in the La Megantic train derailment, clearly the risks were underestimated. The appropriate safeguards – design or human – failed.

There are many risk assessment techniques used by industry and regulators: Failure Modes and Effects Analysis, Probabilistic Risk Assessment, and Hazard and Operability Study (to name a few). Where they tend to underestimate risk has been studied by many independent sources* and has been found to be especially weak in human factors:

- complacency in design

- failure to anticipate vulnerabilities from external sources to the system

- unjustified trust in safety margins

- poor training

- cutting corners to cut costs

- cosy relationship between regulators and the regulated

- cultural factors

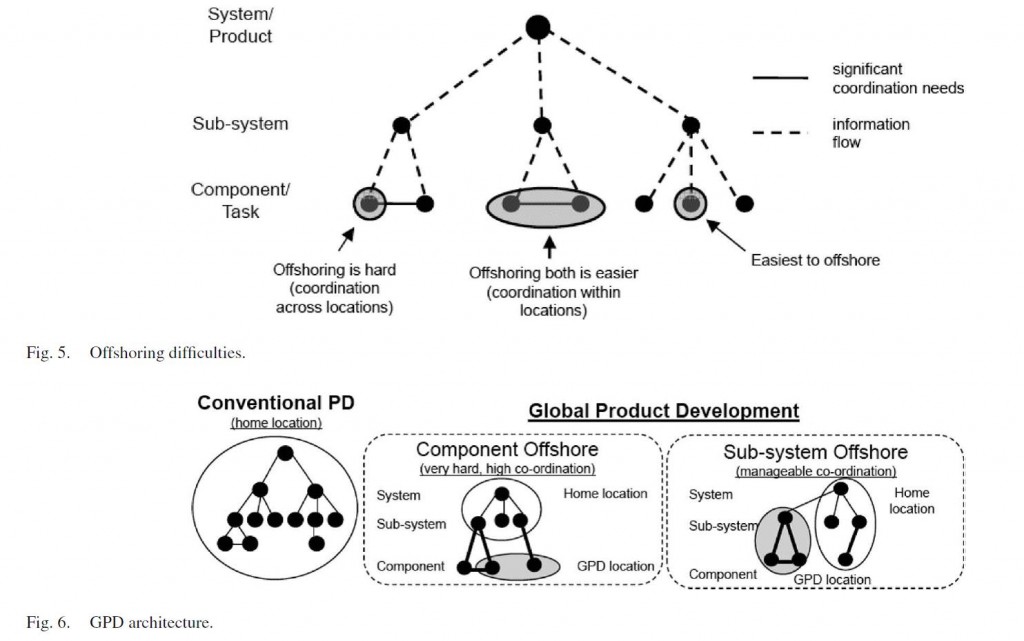

- handovers between individuals or groups from different organizations

Hollywood likes to produce action/disaster movies that illustrate the consequences of accidents and incidents. Sometimes they are overdramatic (the fuel cell explosion in Terminator 3 was like a huge nuclear bomb! If only fuel cells could be so powerful…).

Other times Hollywood seems to be pretty prescient, as in the movie Unstoppable, though that had a happy ending.

Considering the catastrophic consequences of the La Megantic derailment, we need to reconsider oil transport – and not necessarily in favour of pipelines, as pipelines have their unique risks and consequences as well. The La Megantic derailment is bad for oil overall.

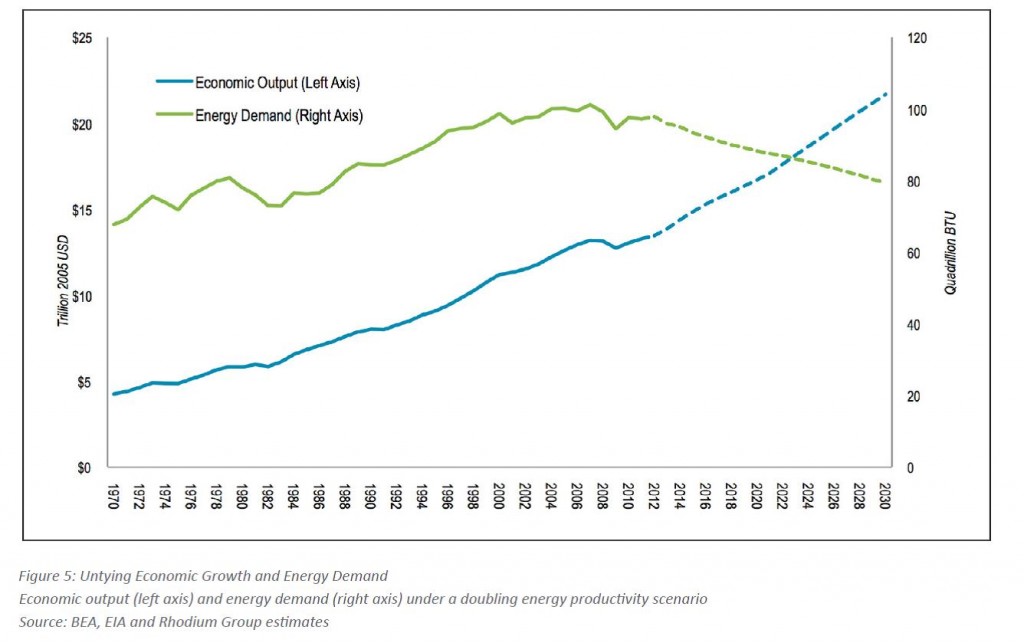

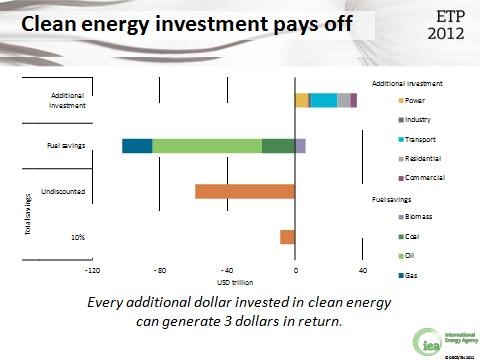

One advantage of many clean energy sources is that the inherent accident risk and consequences are much lower than conventional forms. When assessed through that lens, the overall project and financial returns can be superior.